Dec 22, 2023

iTran

1148

System Value & Business Pain Points

How to realize the accurate positioning of goods in both warehouse and ramp operations has long been a critical challenge in the cargo industry. Cargo positioning not only impacts the efficiency of cargo operation, but also is a key link to minimize labor costs and improve the level of cargo supervision.

iTran’s Locating System achieves real-time and accurate cargo location in warehouses and on ramps without manual intervention. Within the warehouse, the system reaches locating accuracy of 2-3 meters; And on the ramp, the positioning accuracy is maintained at 5-10 meters.

For warehouse locating, iTran perfectly addresses the challenge of real-time location and track replay for cargo by Bluetooth and RFID technology.

For ramp locating, iTran uses solar-powered GPS trackers to help the ramp operation department achieve real-time tracking of Dolly/ULDs. The incorporation of solar and laser sensors enables the system to provide at least two to three years of battery life and better sense the loading/unloading activities on ULDs, helping operation department to effectively monitor flight security status.

Hardware of Warehouse & Ramp Locating System

Bluetooth station

Bluetooth tag

RFID

Forklift kit

GPS with solar Locator (RAMP)

Laser sensor (RAMP)

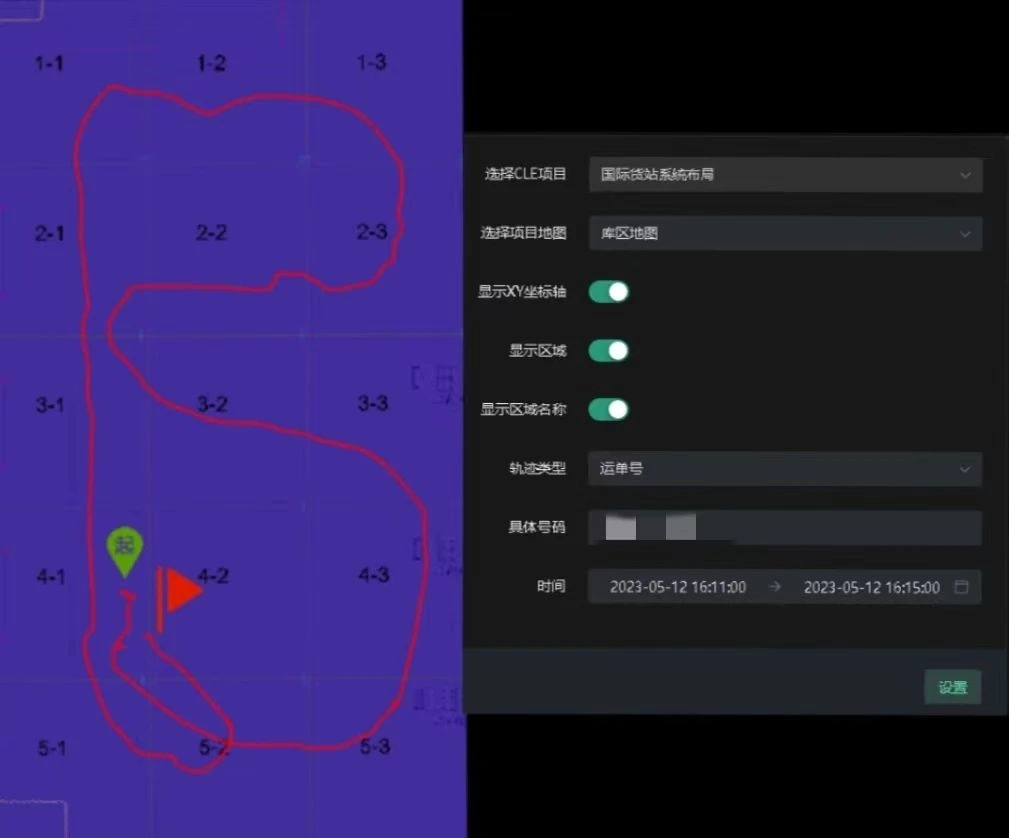

Interface of Warehouse Locating System

(Picture shows warehouse map model)

(Picture shows cargo tracking)

Apron unpowered equipment positioning system interface display

(Hardware installation reference diagram)

(Hardware installation reference diagram)

(Software interface reference diagram)

(Software interface reference diagram)

(Pop-up alerts when the battery is low)

(Pop-up alerts when the device falls off or is removed)